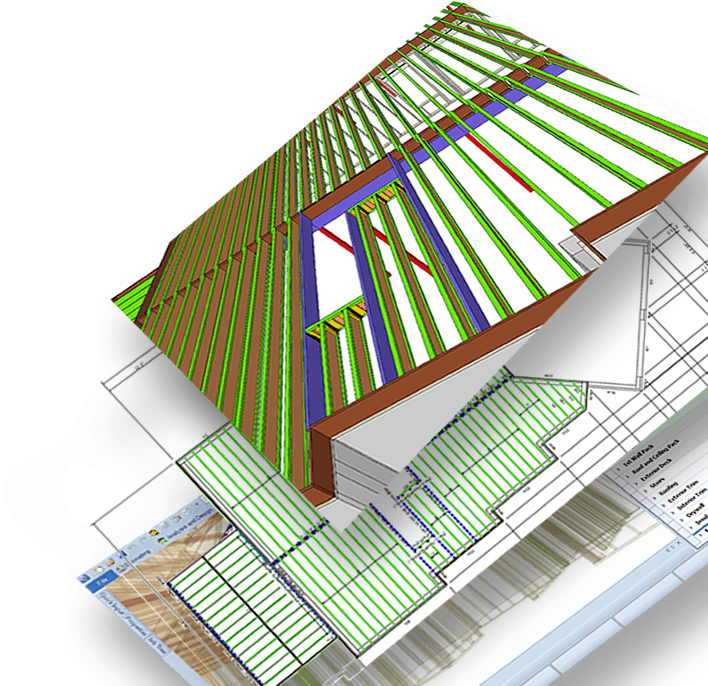

MITEK FLOOR TRUSS ADVANTAGES

Choosing floor trusses over dimensional lumber or I-joists will save time on site, reduce material needs and costs, and enhance design opportunities.

FLOOR TRUSSES

HOW CAN FLOOR TRUSSES IMPROVE YOUR BUILDING PROCESS?

Floor trusses are highly engineered and dependable structures, but many builders don’t realize they also help to eliminate costly materials and maximize design freedom. They have more variety in end conditions than dimensional lumber or I-joists and can be engineered to accommodate design details that benefit the homeowner – like higher ceilings, fewer soffits, and balconies.

- Install fewer framing members – resulting in reduced material costs and install time – because of increased on-center spacing compared to traditional framing methods.

- Value engineered so that span, deflection and load efficiency are unique to each build.

- Reduce material costs in top chord bearing conditions by eliminating exterior rim boards or costly hangers.

- Add trimmable ends to floor trusses for on-site installation versatility.

- Eliminates the need for on-site sawing and increases available space for HVAC, Electrical and Plumbing installation vs other framing methods, which have restrictions limiting the location and size of holes in a joist. Floor trusses remove the confusion for contractors because there is no need to drill holes in the first place.

- Avoid the need forsoffits, with added access to end panels where plumbing drops are common.

- Maximize design freedom by incorporating many architectural details into individual truss designs, such as concealed beams, cantilevers and balconies. These prefabricated designs reduce framing complexity and install time.

- Eliminate unnecessary material costs across the value chain – like concrete, steel and finishing materials – by reducing the number of bearing walls, beams, columns and footings, thanks to longer spans and higher strength capacities.

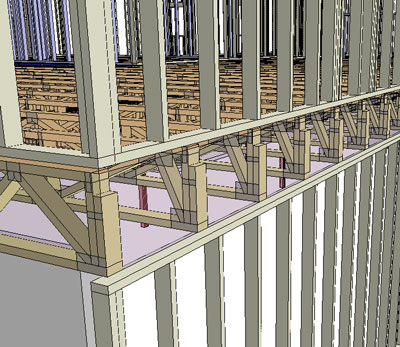

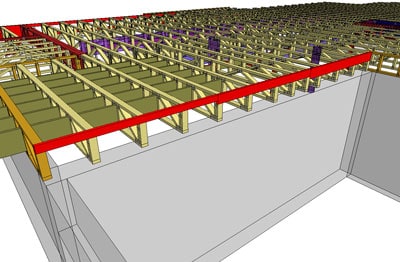

Superior End Reactions

Superior end reaction capabilities eliminates the need for additional structural band-board, web stiffeners, squash blocks or blocking panels.

Gable ends or “Ladder Truss”

Gable end floor trusses, sometimes called “ladders”, provide a strong alternative to large dimensional lumber for parallel closure. Gable end trusses are manufactured along with the main span trusses, ensuring matching height and can include built-in ribbon details.

Open Webbing is Trade “Friendly”

Open webbing provides great benefits to plumbers and electricians, without the need to spend time cutting holes in floor members. Less cutting reduces jobsite labor and reduces potentially critical errors that could result in compromising the structural integrity of the components.

Versatile Floor Depths

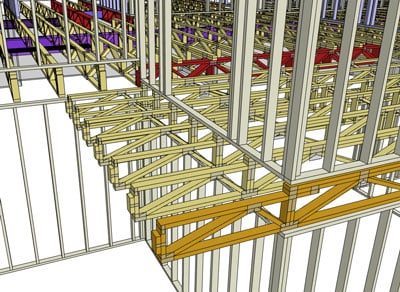

Versatile depths allow floor systems to incorporate sunken floor areas into system. Walls can be framed at a standard height and “steps” in the floor system can be created by the depths of the floor trusses, saving the framer time and the builder money.

Superior Cantilever Distances

Open-web floor trusses provide superior cantilever distances. Far greater than EWP and conventional framing. Cantilevers can include built-in details such as dropped top chords for balcony decking. Open-Web floor trusses can support greater concentrated loads to carry bearing walls and roof loads from above.

Built-In Ribbon Notch for ease of installation and proper edge nailing

Floor trusses feature a built-in ribbon notches that can be built to receive any dimension of 2x lumber desired. Continuous ribbons provide stability for installed trusses, and also provide solid nailing surface for the edge nailing of floor sheathing. This eliminates the need for larger and more expensive “band-board” solutions required by dimensional lumber and other engineered wood products.

Built-in Beam Pockets

Customized beam pockets can be designed into floor trusses to accept various materials inserted through the webs. Trusses can be designed to support load-bearing headers at openings or to carry other floor trusses. Dimensional lumber can be “threaded through” the webs to create exterior balconies that run perpendicular to the direction of the floor trusses. This versatility allows the builder multiple options for framing today’s complex building designs, and saves him money on labor and time to complete the required framing.

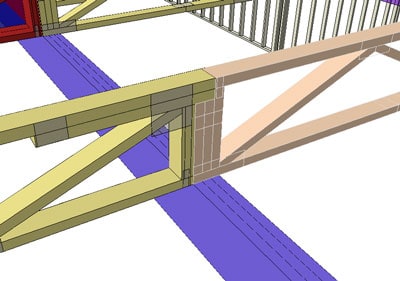

Keyed Bearing Detail

Keyed Bearing” or “Shared Bearing” details allow two different floor trusses to share the same interior bearing and stay aligned, eliminating the need to stagger or overlap the two trusses. Sheathing installation is much easier because the supporting trusses line up, greatly reducing the need to cut special sheathing pieces to complete the subfloor. The result is a cleaner detail, with full bearing while reducing labor and material usage.

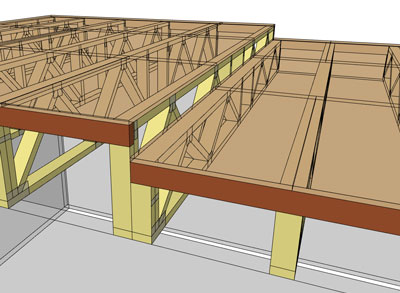

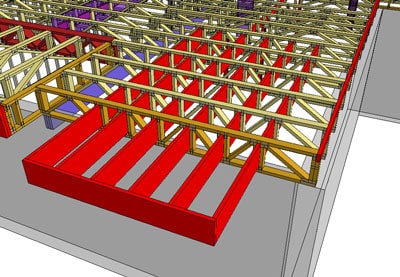

Floor Cassette

Floor Cassettes can be manufactured at the plant and will dramatically decrease installation time. Floor Cassettes typically 10′ wide and are lifted easily with a crane. In the above picture all the continuous lateral bracing and x bracing was built in reducing installation labor even more.